Traditionally, barcodes and RFID technology have been the go-to for efficient shipment tracking. Barcodes use linear data representation, while RFID tags employ radio frequency identification, both serving pivotal roles in simplifying supply chain processes.

However, as we navigate the complexities of modern supply chains, a more efficient alternative has emerged – trackable QR Codes. This article explores the benefits of incorporating QR Codes into logistics operations, offering a practical guide for their seamless implementation.

Benefits of using QR Codes for logistics

Let’s see how QR Codes offer distinct advantages over barcodes and RFID tags.

1. Data capacity

QR Codes store more data, including product details, serial numbers, tracking IDs, and website links. No more separate documents or tedious manual data entry.

2. Versatility

Ditch the dedicated scanners. You can easily scan QR Codes with your mobile device, making them accessible and cost-effective across your entire operation.

3. Real-time tracking

No longer is “out for delivery” a mystery. You can use QR Codes for location tracking by integrating them with real-time tracking systems. Pairing this with a multi-stop route planner ensures seamless navigation and efficient deliveries.

🧠 Did you know?

43% businesses use QR Codes to improve their logistics tracking.

Discover more such interesting insights in our State of QR Code Report!

4. Dynamic updates

Dynamic QR Codes allow you to change the destination link anytime. So, you’re not stuck with costly reprints if you need to change the tracking link, product info, or other crucial information.

5. Customization

QR Codes are fully customizable. You can change QR Code shape, color, background, pattern, and add your logo or CTA. Custom QR Codes become distinctive markers of authenticity, preventing duplication and tampering.

Top 5 ways of using QR Codes in logistics

1. Inventory management

Tired of manual counts and misplaced pallets? Assign unique QR Codes to each product or batch, enabling quick and accurate updates to inventory records. Scanning becomes a breeze, updating inventory records with accuracy and speed.

Suggested read: How To Use QR Codes for Inventory Management?

2. Package tracking

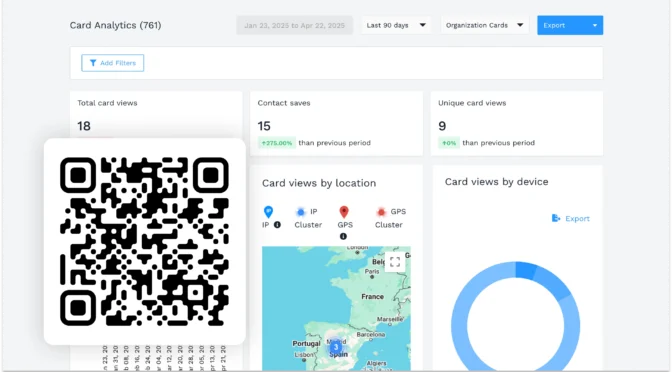

Integrate QR Codes with real-time QR code tracking software and embed them on shipping labels. Every scan triggers a location update in your tracking software, providing real-time visibility into the movement of packages.

3. Last-mile delivery

Scanning QR Codes on packages provides instant access to recipient details, delivery instructions, and real-time route updates. No more wrong turns or forgotten instructions!

4. Multi-lingual parcel instructions

Utilize QR Codes to offer instructions, care guidelines, or product information in multiple languages. Customers and logistics personnel can scan the code for information in their preferred language, improving communication and reducing the risk of mishandling.

Suggested read: How to create a multilingual QR Code?

5. Streamlined returns and reverse logistics

Simplify the returns process by allowing customers to initiate returns with a QR Code scan. Upon return, you can scan the QR Code to update inventory records, initiating reverse logistics operations automatically.

How to implement QR Codes in logistics

1. Define objectives and use cases

Clearly define the objectives of incorporating QR Codes into your logistics processes. Identify specific use cases such as inventory management, package tracking, last-mile delivery, or returns. Understanding the goals will guide the customization and integration process.

2. Choose a reliable QR Code generator

Select a reputable one that suits your specific logistics needs. Some essential logistics features to look out for when choosing a QR Code generator are bulk QR Code generation, API and integrations, tracking capabilities, and customization options.

If you use Uniqode, apart from the feature above, you also get access to the following features:

- Enterprise-grade security with GDPR, HIPAA, & SOC® 2 Type 2 compliance, and ISO 27001:2022 certification.

- Easy collaboration and access management with admin and sub-accounts.

- Automation capabilities are available through third-party tools such as Zapier, Workato, Webhooks, etc.

3. Integrate QR Code with existing systems

Integrate your QR Code data with a Warehouse Management System (WMS) or Enterprise Resource Planning (ERP) software. Implementing best practices and warehouse management tips can further optimize this integration, ensuring that QR Code information synchronizes efficiently with your broader logistics infrastructure

If you use Uniqode, follow the steps below to integrate your application of choice with our QR Code API,

- Sign up for a free API trial.

- Get the developer token key (API key).

- Create a QR Code and customize it.

- Test the QR Code to check scannability and analytics.

- Download the QR Code.

4. Employee training

Train relevant staff on QR Code scanning procedures and their role in improving operational efficiency. Familiarize employees with using QR Codes for different logistics processes to ensure a smooth transition.

5. Generate and print QR Codes

Create QR Codes for items or packages that require tracking. Include essential information such as SKU numbers, batch details, or tracking IDs. Consider utilizing bulk QR Code generation for scalability, especially in warehouses with high volumes of products.

If you use Uniqode, follow the steps below to create thousands of QR Codes in under 5 minutes:

- Go to Uniqode’s QR Code Generator and log in to the dashboard.

- Go to the QR Codes section on the left panel.

- Click on Bulk Upload.

- Choose the QR Code type.

- Upload your QR Code inventory management data as a CSV file.

- Customize different elements of the QR Code design. Change colors, add your brand logo, include CTA frames, etc.

- Create a label for your batch for easy sorting and organization later on.

- Submit your bulk creation request.

6. Rollout QR Code implementation

Roll out the implementation of QR Codes across the logistics operation in a phased manner. Start with a pilot project to identify any potential issues before full-scale implementation. Solicit feedback from staff to make necessary adjustments.

Frequently Asked Questions (FAQs)

1. How do QR Codes work for shipping?

QR Codes simplify shipping by storing detailed information such as product details, serial numbers, tracking IDs, and website links. Integrated with real-time tracking systems, they provide instant visibility into the location and status of packages throughout the supply chain. Scanning QR Codes on shipping labels triggers location updates, enhancing real-time tracking.

2. Why are QR Codes important in logistics?

QR Codes offer distinct advantages over traditional methods like barcodes and RFID tags. They store more data, are versatile, and enable real-time tracking. With features like dynamic updates and customization, QR Codes streamline inventory management, package tracking, last-mile delivery, and returns, making logistics processes more efficient and accurate.

3. Why is a QR Code better than a barcode?

QR Codes outperform barcodes regarding data capacity, accessibility, and real-time tracking. They store more information and can be easily scanned with mobile devices, eliminating the need for dedicated scanners. The dynamic nature of QR Codes, allowing updates and customization, makes them a superior choice for modern logistics operations.

4. Is it safe to use QR Codes in logistics?

The safety of using QR Codes in logistics depends on the QR Code generator you choose. Opting for a GDPR, HIPAA & SOC® 2 Type 2 compliant, and ISO 27001: 2022 solution guarantees stringent data protection and security standards, offering confidence in the safety and reliability of QR Code usage in logistics.

Nidhi is a content marketer at Uniqode, where she explores the phygital world one scan at a time. When she’s not praying to the SERP gods to get her content noticed, you’ll find her teaming up with product folks to decode the tech behind QR Codes and exploring fresh use cases for these tiny squares and circles. She also lives for customer conversations and goes full detective mode on Reddit, uncovering insights like she’s working on a true crime case. She scans every QR Code she finds, analyzing the tech behind them and critiquing campaigns (yep, Taylor Swift’s included). If you’re curious about what QR Codes can do (spoiler: they can do SO much), she’s your go-to guide for understanding their full potential.